PURPOSE AND SCOPE OF APPLICATION

PURPOSE AND SCOPE OF APPLICATION ZKG-P series polyamide explosion-proof heated cabinets for I&C are used for protection of I&C against negative impact of low temperature, precipitation, dirt, dust and other aggressive environmental factors. The cabinets are located on open sites and in unheated rooms for installation of various Ex equipment, as well as enclosures of local control stations and cabinets if their installation in hazardous areas is required.

Area of application: depending in the chosen version and explosion protection marking, the products can be installed in zones 1, 2, 21, 22 and provide explosion protection in explosive mixtures of categories II, III of group IIA, IIB, IIC, IIIA, IIIB, IIIC.

1Ex db e IIC T3 Gb (

1Ex db e IIC T3 Gb ( 1Ex e IIC T3 Gb X (

1Ex e IIC T3 Gb X ( 1Ex e IIC T3 Gb X (

1Ex e IIC T3 Gb X ( II Gb IIC T3 X (

II Gb IIC T3 X ( II Gb IIC T4 X (

II Gb IIC T4 X ( II Gb IIC T5 X (

II Gb IIC T5 X ( II Gb IIC T6 X (

II Gb IIC T6 X ( IIGb

IIGb Ex e IIC Gb U

Ex e IIC Gb U Ex tb IIIC Db U

Ex tb IIIC Db U II Gb IIC или II Gb IIB

II Gb IIC или II Gb IIB

Remark: For option /SHINA Z, bus bars with 2 holes x 16 mm2 and a row of holes 6 mm2 are installed by default (the quantity depends on the bus bar length). Installation of bus bars with different diameter of holes is possible upon customer’s approval.

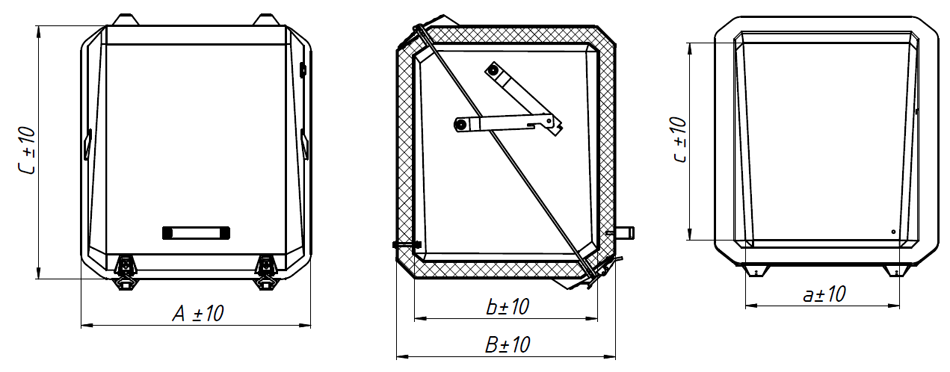

| Dimension type | А, mm | B, mm | C, mm | a, mm | b, mm | Mass, kg |

| ZKG-P514959 | 510 | 490 | 590 | 400 | 366 | 20 |

| ZKG-P | - | Х | / | Х | / | Х | – YU 27.12.23-060-72453807-2017 |

| Device type | |||||||

| Enclosure size code | |||||||

| Type of mount: wall mount - S; pipe - T; rack mount - SH |

|||||||

| Options, accessories and versions |

Example: ZKG-P514959/S/SHINA/OBOGREV-TU 27.12.23-060-72453807-2019

For heating of internal volume of ZKG protective housings, use heater module GTG-MODULE, Ex heater GTG-RADIATOR2 or GTG-PLASTINA1.

| I&C cabinet | Heating power, W |

| ZKG-P514959 | 100 |

| Electric heater | Explosion protection marking |

| GTG-MODULE Ex heater module |  1Ex d e IIC T3 Gb 1Ex d e IIC T3 Gb |

| GTG-RADIATOR2 Ex heater |  1Ex e II T3 Gb X 1Ex e II T3 Gb X |

| GTG-PLASTINA1 Ex heating plates |  1Ex e II T3 Gb X 1Ex e II T3 Gb X |

| Electric heater | Maximum surface temperature, °С | Explosion protection marking |

| Water/steam heating not higher than 195 °C | 200 |  II Gb IIC T3 X II Gb IIC T3 X |

| Water/steam heating not higher than 135 °C | 135 |  II Gb IIC T4 X II Gb IIC T4 X |

| Water/steam heating not higher than 95 °C | 100 |  II Gb IIC T5 X II Gb IIC T5 X |

| Water/steam heating not higher than 80 °C | 85 |  II Gb IIC T6 X II Gb IIC T6 X |