PURPOSE AND SCOPE OF APPLICATION

PURPOSE AND SCOPE OF APPLICATION

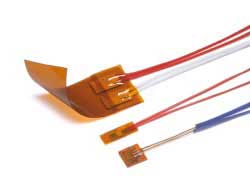

We have the innovative technology of industrial heating using heating silicone armored plates and tapes. Heating plates and tapes are manufactured from the top-quality silicones, resistance metals and fiberglass threads. Reducing of production costs enabled to use the plates not only in aviation industry, but also in the production of spacecraft.

Heating plates and tapes more efficiently conduct heat, they are easy to mount and their scope of application is larger that that of heating cables. A bimetallic switch or a temperature probe built in the plate helps to more efficiently control the temperature. Heating plates and tapes are resistant to dirt and moisture, chemically aggressive atmospheres, resistant to frost (tested at temperatures -66 °C), tolerate well the destructive effect of UV rays.

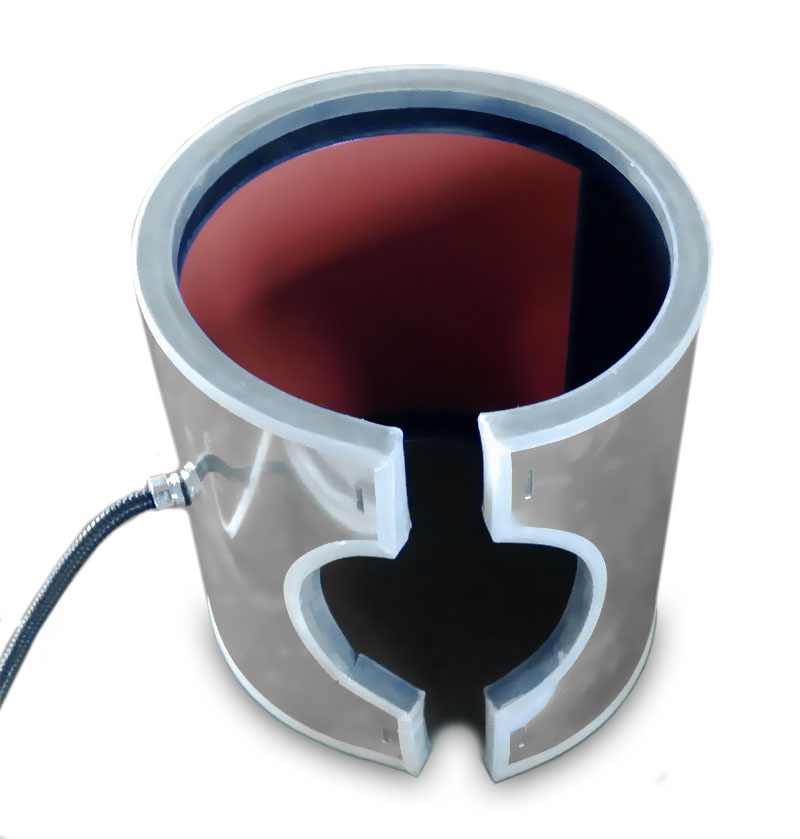

Explosion-proof heating plates are intended for heating of flat and curved surfaces, such as reservoirs with petroleum products, containers, pipes surfaces, reservoirs with lubricants, heating of materials being refined, technological structures, hydraulic drives and joints of power devices, etc.

Explosion-proof heating plates are manufactured from special heat-resistant rubber; they have an earthing grid, an explosion-proof gland for power connection. The plates are fastened directly to the heated surfaces of technological objects and structures and are intended for operation in the harshest operating conditions, where resistance of the equipment to wide temperature ranges, moisture and dust is required.

Upon customer‘s request, explosion-proof heating plates may be completed with temperature control devices.

| Model | Type | Heating temperature, °C |

| DVG-TERMOSTAT2-(-5/13)1 | Fixed temperature | 7-13 |

| DVG-TERMOSTAT2-(0/18)1 | 12-18 | |

| DVG-TERMOSTAT2-(60/78)1 | 72-78 | |

| GTG-PT | Programmable temperature |

0...120 |

Scope of application – outdoor and indoor hazardous areas and pits non-hazardous with gas or dust, as per explosion protection marking, GOST 30852.13-2002 (IEC 60079-14:1996), areas with presence of combustible dust, as per GOST IEC 61241-3-2011, dangerous production facilities of I, II, III, IV hazard class supervised by Rostechnadzor of the RF and national technical supervision bodies of the Customs Union and CIS countries.

Minimum order: 50 pcs.

| Scope of application of heating plates | |||

|

|

|

|

| Heating of metal structures and reinforced iron for repair works | Heating of pipes surfaces | Heating of flexible hoses and movable tanks | Heating of containers with lubricants in industrial equipment |

|

|

|

|

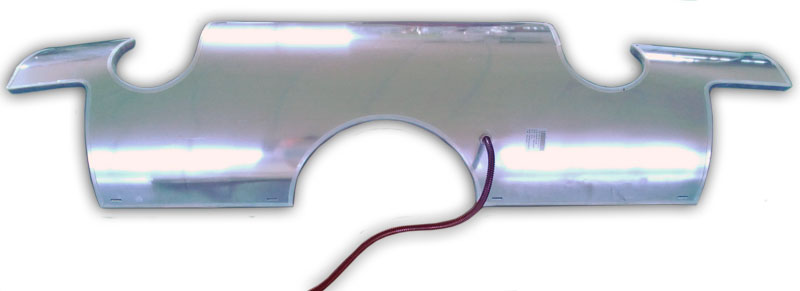

| Heating of reflectors and movable elements of parabolic antennas | Heating of parts of aerospace structures | Heating of hydraulic drives and joints of power devices | Prevention of freezing of pumping chambers |

|

|

|

|

| Heater of optical elements of video cameras | Heating of refined materials | Heating elements for drying modules in textile industry |

Heating of collectors and dust collectors |

|

|

|

|

| Using in hot compressing units | Heating of reservoirs of proportioning devices | Heater of photosensitive materials | Heater for fixation of paint in high speed typographic devices |

|

|

|

|

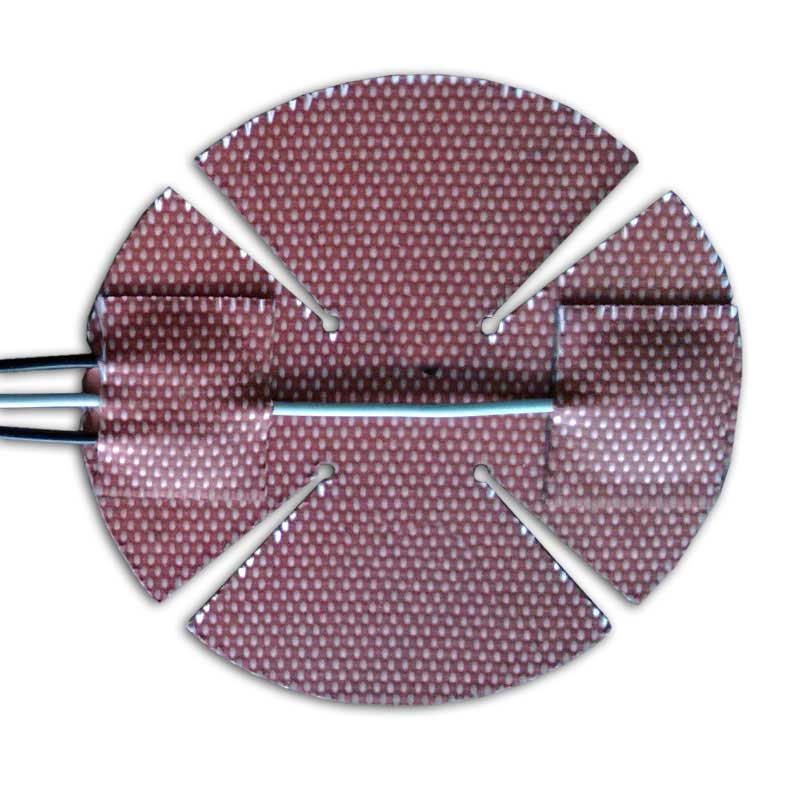

| Application of plates in dryers | Devices for paraffin drying for dryer | Heating of cuttings for wood processing industry | Heating of plates for production of semiconductors |

|

|

|

|

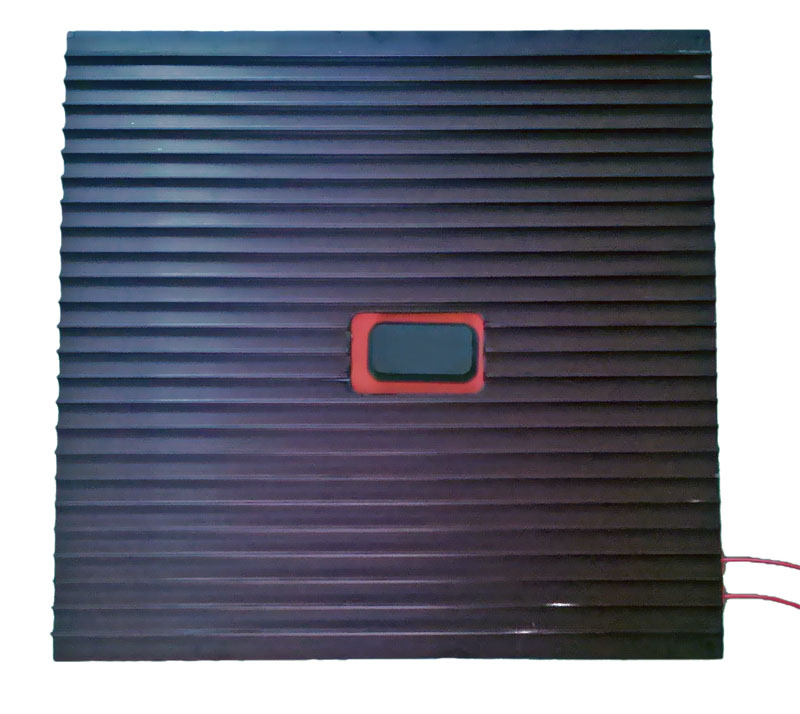

| Application of plates in cutting-edge medical equipment | Heating formwork for concrete works in polar zones | Physical and chemical laboratory equipment | Heating of molds for plastic molding |